Specialised Glass Machinery & CNC Electrical Maintenance Support in Melbourne

Electrical servicing for specialised CNC machines.

Scroll

gallery

Electrical servicing for specialised CNC machines.

Glass processing and CNC machines need steady, accurate electrical setups. We keep your machines powered correctly and fix faults fast—so production stays smooth and downtime stays low.

ABOUT

CNC & Glass Machinery Electrical Support | Reliable Nationwide Service

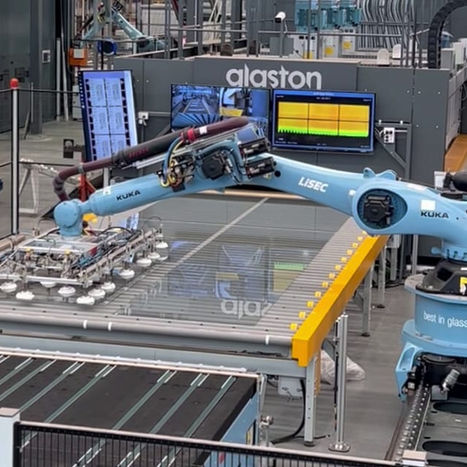

EES Electrics provides specialised support for glass-processing machinery and CNC systems that demand accuracy, stability, and consistent electrical performance. The team focuses on cnc machine electrical maintenance that keeps high-speed tools running safely across production environments. Each service reflects a detailed understanding of electrical behaviour within modern machining centres and glass-fabrication lines. This approach ensures dependable machine output and long-term system reliability for industrial operators across Australia.

Specialist CNC Machine Electrical Maintenance

CNC electrical maintenance matters because high-speed machining relies on stable power, precise control signals, and accurate feedback loops. EES Electrics delivers cnc machine electrical maintenance designed to detect issues before they disrupt machining performance. Examples include identifying servo drive irregularities, reviewing spindle load behaviour, and checking motor temperature patterns during heavy cutting cycles. These insights help avoid quality defects and protect critical equipment.

The team also provides structured cnc electrical maintenance to stabilise components such as contactors, sensors, and motor drives. Tasks involving cnc electric system calibration and targeted checks of cnc electrical assemblies support predictable workflow performance. These maintenance efforts improve reliability, safeguard essential machinery, and support stronger production continuity across all manufacturing environments.

CNC Electrician Expertise for Industrial Manufacturing

Specialised expertise matters because CNC systems combine electrical power, computer control, and mechanical precision in a single environment. EES Electrics brings proven experience through qualified cnc electrician professionals who understand the demands of industrial-grade machinery. Examples include repairing control circuit faults, tuning drive signals, and adjusting power supplies for stable controller operations. These tasks require a deeper understanding than general electrical work.

Technicians apply broad knowledge of cnc electrical systems and the complexity found in cnc machines electrical environments, including rapid tool changes, multi-axis coordination, and programmable routines. This detailed approach provides facilities with dependable support and fewer unplanned interruptions, helping maintain the performance standards necessary for competitive manufacturing.

CNC Electrician vs General Electrician

Understanding the difference helps organisations choose the right specialist.

A CNC electrician focuses on diagnostics, controller interfaces, PLC communication, and load-calibration tasks that keep precision machinery operating safely. Their work includes analysing feedback loops, correcting wiring that affects drive synchronisation, and ensuring stable voltage control for sensitive systems. This level of detail is essential for equipment that relies on tight tolerances.

A general electrician maintains strong foundational skills across installation, repairs, and commercial power systems. They manage essential electrical tasks but may not specialise in controller logic, servo behaviour, or machine-tool accuracy requirements common in CNC environments. Their work remains valuable but does not cover all machine-specific demands.

Both roles support facility operations, although CNC machinery performs best when guided by specialists who understand the technical depth required, allowing businesses to make the choice that fits their operational needs.

Electrical Services for CNC Machines and Glass-Processing Equipment

Comprehensive service matters because CNC and glass-processing systems operate under continuous demand and require precise electrical oversight. EES Electrics delivers targeted support for motors, drives, safety interlocks, limit switches, and controlled power distribution. Examples include verifying drive response times, aligning limit-switch logic for consistent travel accuracy, and ensuring motors behave correctly during rapid or high-load operations.

This expertise extends to cnc machines electrical service, ensuring equipment remains calibrated and safe throughout production cycles. The team also handles broader cnc machines electrical requirements for routers, machining centres, and automated glass-processing tools. Additional support through cnc machine maintenance service electrical ensures that system updates and repairs align with manufacturer expectations. These services enhance operational efficiency and promote long-term equipment stability.

Support for Wood, Metal and Glass CNC Systems

Industry coverage matters because each CNC environment has different electrical demands and mechanical behaviours. EES Electrics provides solutions that support metal-working machines, routers, laser cutters, and glass-processing systems with equal reliability. Examples include balancing load distribution, adjusting spindle behaviour to stabilise cuts, and ensuring lubrication systems perform correctly during continuous operations.

Facilities that rely on specialised tools benefit from targeted wood cnc machine electrical maintenance, which addresses dust-dense environments, rapid cycle movements, and greater stress on drive components. These services support smoother processing, consistent material output, and reduced risk of electrical faults in high-performance production lines.

Preventative CNC Maintenance and Performance Optimisation

Preventative maintenance matters because CNC faults often begin as small electrical variations. EES Electrics provides cnc machine electrical maintenance that includes heat signature reviews, vibration trend analysis, and wear-pattern detection. Examples include identifying early motor strain through thermal readings or detecting drive instability before it affects machining tolerance. These checks support predictable performance planning.

Routine tasks also include torque verification, power quality checks, and controller memory reviews. This structured approach supports detailed cnc electrical maintenance, improving uptime and reducing response times for repairs. By focusing on preventative strategies instead of reactive repairs, EES Electrics helps businesses maintain consistent output and reduce the risk of unexpected machine stoppages.

Integration, Upgrades and Control System Support

Upgrades matter because machinery must adapt as production demands evolve. EES Electrics supports controller replacements, wiring-harness upgrades, and sensor retrofits that help CNC and glass-processing machines integrate with modern automation systems. Examples include upgrading legacy controllers, improving grounding systems for sensitive electronics, or installing new sensors that enhance real-time accuracy.

These updates improve machine stability and operational safety by ensuring compatibility with current production workflows. The improvements help facilities streamline daily tasks, maintain higher output quality, and rely on safer long-term performance across their machining assets.

Why Manufacturers Choose EES Electrics

Manufacturers prefer EES Electrics because the company brings deep experience across CNC, automation, and glass-processing machinery. Technicians understand the electrical demands of servo drives, high-speed tooling, and multi-axis systems. Examples include refining CNC coordination for heavy machining or stabilising electrical supply for precision glass-cutting machines. These insights support safer and more predictable operations.

The combination of skilled cnc electrician professionals and structured processes for cnc machine electrical maintenance builds trust across production environments. EES Electrics focuses on clear communication, consistent reporting, and careful workmanship. This approach strengthens equipment reliability, enhances production flow, and supports long-term operational certainty across all manufacturing sectors.

Conclusion

Reliable CNC and glass-machinery performance depends on accurate electrical support and thoughtful maintenance practices. EES Electrics provides specialised solutions that optimise machine behaviour, protect essential components, and stabilise high-speed environments. By delivering targeted electrical services and consistent cnc machine electrical maintenance, the company helps businesses improve system reliability and support dependable production outcomes across every shift.

Other Service That We Provide

FAQs

1. What is thermal imaging and why is it important for electrical safety?

Thermal imaging identifies abnormal heat patterns that signal early electrical faults. It supports safer operations by revealing issues before they affect system reliability.

2. How often should thermal imaging inspections be carried out?

Most facilities schedule thermal imaging inspections as part of routine maintenance. Regular scans help detect subtle temperature changes early and stabilise asset performance.

3. What types of issues can thermal imaging of electrical systems reveal?

It can detect hotspots, insulation fatigue, loose connections, and uneven loading. These insights help teams address risks before equipment fails.

4. Does thermal imaging of switchboards require shutting down power?

Switchboards can usually be scanned while energised to capture accurate thermal behaviour. This allows technicians to assess electrical conditions without interrupting operations.

5. What is thermographic testing of electrical equipment used for?

Thermographic testing of electrical equipment evaluates motors, panels, and high-load systems. It helps identify heat stress that affects long-term performance.

6. How do electrical thermal imaging services support maintenance planning?

Electrical thermal imaging services provide evidence-based temperature data for repair scheduling. This helps prioritise maintenance and reduce downtime.

7. Are thermal imaging services suitable for large industrial facilities?

Yes, thermal imaging supports manufacturing plants, warehouses, and utilities. It improves visibility across complex systems and heavy-load environments.

8. Can thermal imaging inspections help with compliance or insurance requirements?

Thermal imaging inspections create documented evidence of electrical conditions. These reports often support audits, insurance reviews, and safety planning.

9. Do thermal imaging services work for multi-site or national operations?

Thermal imaging can be deployed across regional and major centres, including thermal imaging Adelaide and thermal imaging Sydney. This ensures consistent reporting across all facilities.

10. How does thermal imaging compare to traditional electrical inspections?

Thermal imaging reveals hidden heat-related issues that visual checks may miss. Using both methods together strengthens electrical reliability and maintenance accuracy.

Let’s Talk About Electrical Service Solutions For You.

Reach out for a quote, emergency callout, or project consultation.

Get in touch

What Our Clients Say About the Quality, Reliability, and Expertise Behind Our Work

TESTIMONIALS

“EES Electrics helped us get back online after a serious fault. They arrived in under an hour—super professional and efficient.”

Operations Manager

Beverage Plant - VIC

“Really impressed by their thermal imaging service. Identified a major switchboard issue before it became a disaster.”

Maintenance Lead,

Food Processing Facility, NSW

“They took full control of our automation upgrade and delivered on time, with no disruption to production.”

Factory Manager,

Industrial Glass Manufacturer - SA

“Professional, responsive, and they speak in a way that non-technical people like me can understand.”

Plant Owner,

Food Business, VIc

“From initial consultation to installation, their team was easy to work with and clearly knew their stuff.”

Senior Manager

Logistics

“Reliable electrical partner for our nationwide operations. No matter the state, they show up and get it done.”

Owner

Food Business Owner, VIC