Industrial Electrical Consulting Melbourne

- EES Team

- Oct 6, 2025

- 2 min read

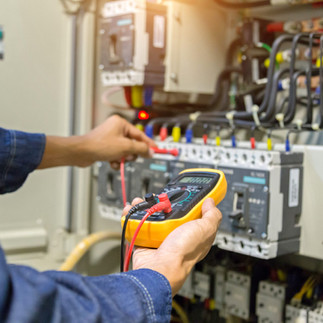

A recent incident in Melbourne highlighted the critical importance of reliable refrigeration systems. An electrical fault in a pizza takeaway's fridge led to a blaze, underscoring the potential hazards when such systems fail. This event serves as a stark reminder of the risks food manufacturers face when their cooling equipment malfunctions. Implementing industrial electrical consulting in Melbourne can help prevent such costly and dangerous situations. EES Electrics Pty Ltd specializes in identifying and mitigating electrical issues before they lead to significant problems, ensuring continuous and safe operations for food and manufacturing plants

Everyday Electrical Headaches in Food Manufacturing

Temperature failures: Refrigeration instability spoils stock.

Compliance risks: Electrical faults can violate HACCP and safety standards.

Rising energy bills: Overworked motors and inefficient circuits increase costs.

Reactive maintenance costs: Constant emergency repairs disrupt schedules and budgets.

How Electrical Consulting Helps

EES Electrics Pty Ltd provides:

Electrical System Audits: Detect hidden risks before they cause downtime.

Power Quality Assessments: Reduce energy waste and protect sensitive equipment.

Design & Upgrade Recommendations: Future-proof your plant for expansion.

Preventative Maintenance Plans: Minimize emergency breakdowns.

Compliance Assistance: Ensure AS/NZ standards are met confidently.

Benefits of Industrial Electrical Consulting Melbourne

Save Money: Cut energy bills and emergency repair costs.

Ensure Food Safety: Maintain refrigeration and production line stability.

Reduce Risk: Fewer emergency callouts and unplanned downtime.

Plan Growth Confidently: Add new machinery without overloading your electrical system.

Mini Case Example: A Melbourne cold storage warehouse reduced energy penalties by 18% after an industrial electrical consulting audit from EES Electrics Pty Ltd identified and corrected power factor issues.

Choosing the Right Consultant

Look for:

Relevant experience: Work with cold storage, bakeries, or food plants.

Hands-on expertise: Senior technicians, not just junior staff.

24/7 support: Electrical issues don’t follow business hours.

Proven results: Ask for mini case studies or metrics, not just promises.

Solving the #1 Pain Point: Spoilage & Compliance

Spoilage isn’t just lost product it risks retailer trust, regulatory fines, and sometimes your license to operate. Industrial electrical consulting Melbourne prevents this domino effect by stabilizing systems and planning upgrades strategically.

Don’t wait for the next breakdown or compliance warning. Book industrial electrical consulting in Melbourne with EES Electrics Pty Ltd today and protect your plant from costly failures.

If you’re not sure whether your plant’s electrical system is costing you more than it should, check out our previous blog on Power Quality Testing in Melbourne. It explains how unstable power can silently drain profits, damage equipment, and cause costly downtime, and how a simple audit can stop it before it starts. FAQ

Q1. What is industrial electrical consulting in Melbourne?

It’s expert guidance and auditing to optimize your plant’s electrical system, prevent downtime, and ensure compliance.

Q2. How does consulting help food manufacturers save money?

By reducing energy waste, preventing spoilage, and avoiding emergency repair costs.

Q3. Is consulting only for large plants? No. Any facility that depends on reliable, safe electrical systems benefits from consulting.

Choose EES for Industrial Electrical Consulting Melbourne

Electrical consulting isn’t just about keeping the lights on, it's about protecting products, staying compliant, and saving thousands. EES Electrics Pty Ltd brings 30+ years of hands-on experience to Melbourne manufacturers, ensuring safety and efficiency go hand-in-hand.

Thank you for reading. Protect your plant, profits, and peace of mind today

Comments